#FREE ARTCAM ALTERNATIVE SOFTWARE#

Step 3: Use CNC software to process the G-Code to run the machine in the desired manner.Step 2: Convert the vector file to G-Code using Computer-Aided Manufacturing (CAM) software.5 Best CAD software that support CNC Machining.Top free Drawing Exchange Format (DXF) file sites are.Step 1: Create a vector file (DXF) using a Computer-Aided Design (CAD) software.

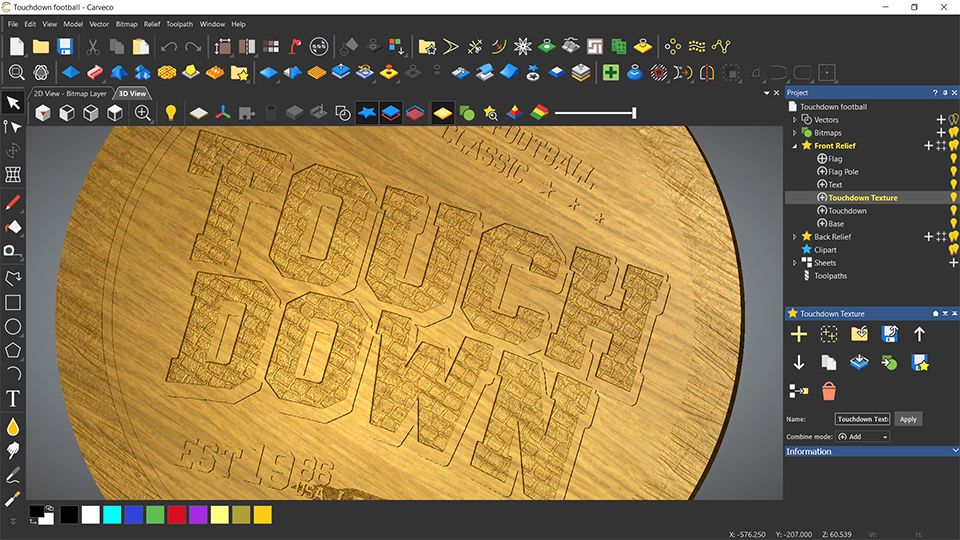

We have curated the article from our own experience and research which will enable you to find the best software for CNC machine but also multiple different options which are both paid and free. Since we know that a lot of our readers are newbies who are looking for the best woodworking tools and recommendations. G- Code is used to communicate with the CNC machines and enables the machine to move in the desired pattern. This design is converted to G-Code using CAM program.Īlso read about the difference between CNC router file vs Laser cutter file Extension You first need a design in a vector file, unless you already have G-Code. These formats can be used across platforms.įrom design to manufacturing stage, a CNC machine uses three different kinds of softwares namely, CAD, CAM and CNC controller software. In CNC machining, the commonly used file formats are STEP and IGES. It is capable of controlling the speed of rotation and rate of the movement. G- Code is programmed in such a way that it controls the movement of a machine by adjusting the position of x, y, and z-axis. Alternate to G-Code, there are Heidenhain and Mazak also in use. The primary CNC programming language is G-Code. Each part of the machine requires its own CNC program. A Computer Numerical Control (CNC) software enables to create programs to run a machine tool.

0 kommentar(er)

0 kommentar(er)